Niron All Pro

New System of PRE-INSULATED PIPES, FITTINGS

NIRON ALL-PRO is the new System of PRE-INSULATED PIPES, FITTINGS and ACCESSORIES dedicated to the transport of hot and cold fluids, considerably reducing heat losses in long sections.

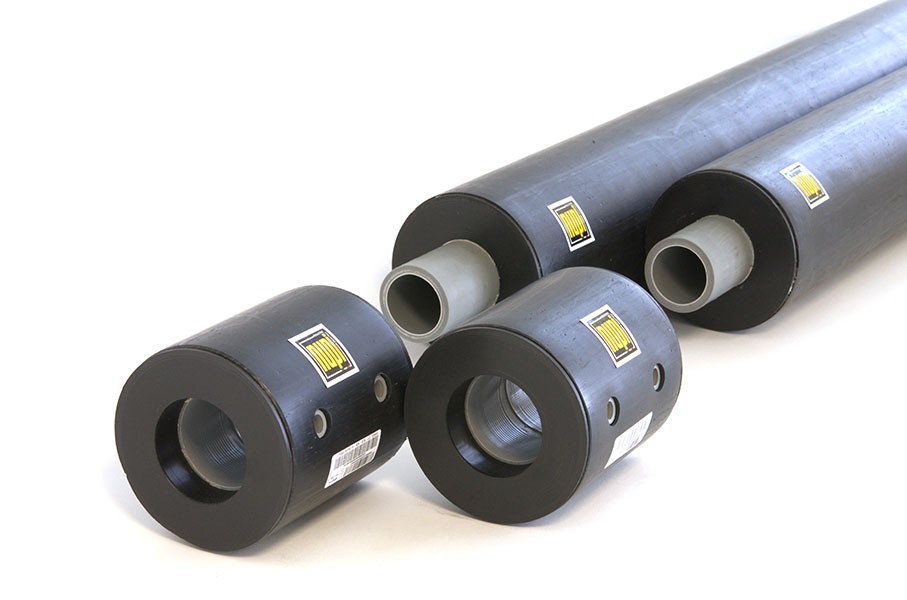

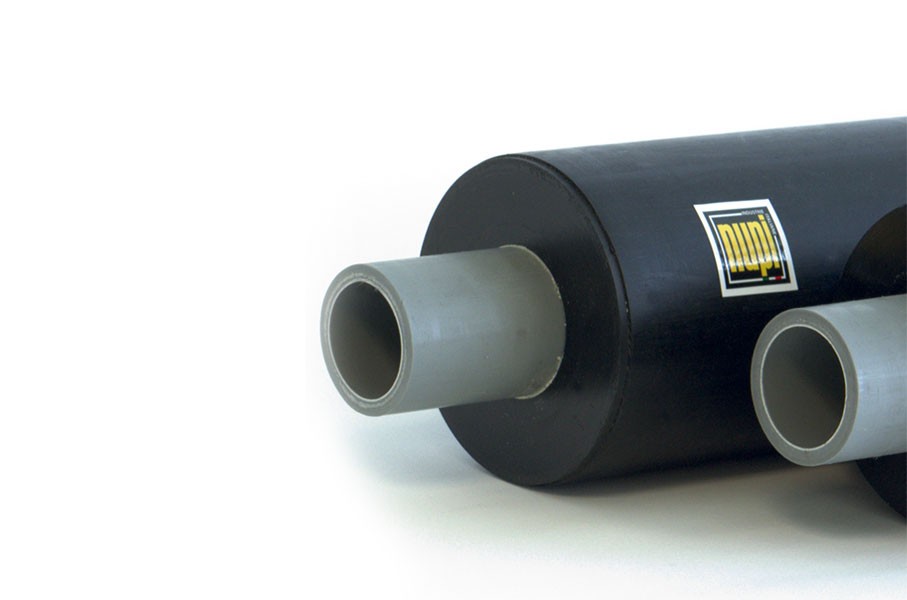

PRE-INSULATED PIPE: COMPOSITION

- SERVICE PIPE OR PRIMARY PIPE (NIRON β)

- THERMAL INSULATION (PUR)

- JACKET PIPE (HDPE)

The real innovation: WELDING METHODS

The NIRON ALL-PRO system allows to carry out joining in two different ways: electrofusion welding (EF) and simultaneous butt welding (BFX2). Pipes and fittings have been designed to optimize installation times on site and, at the same time, to offer a system designed to reduce the thermal drops of the transported heat transfer fluids.

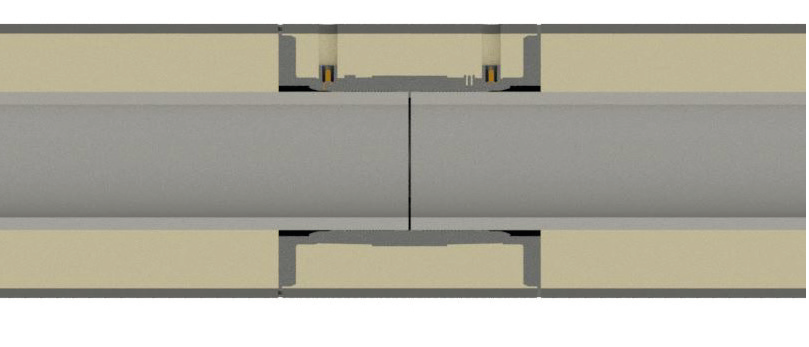

ELECTROFUSION WELDING: includes pre-insulated fittings that hold electrical resistances connected to external connectors that can be welded using welding units normally used for electrofusion joining. The innovation lies in that a single step allows to have an ALREADY PRE-INSULATED JOINT, thus allowing the reduction of installation times by at least 50%, and avoiding the long operations of restoring the insulation in the areas involved in the joining operation.

ELECTROFUSION WELDING: includes pre-insulated fittings that hold electrical resistances connected to external connectors that can be welded using welding units normally used for electrofusion joining. The innovation lies in that a single step allows to have an ALREADY PRE-INSULATED JOINT, thus allowing the reduction of installation times by at least 50%, and avoiding the long operations of restoring the insulation in the areas involved in the joining operation.

Pipes with EF terminals are designed to accommodate the installation of NIRON ALL-PRO electrofusion fittings without the need for cuts to size the lengths of the spigots.

The range of fittings also offers a wide range of combinations that adapt to the many requirements of the installation (branches, valves, tests, and end of line fittings).

WELDING OF ELECTROFUSION PRE-INSULATED FITTINGS

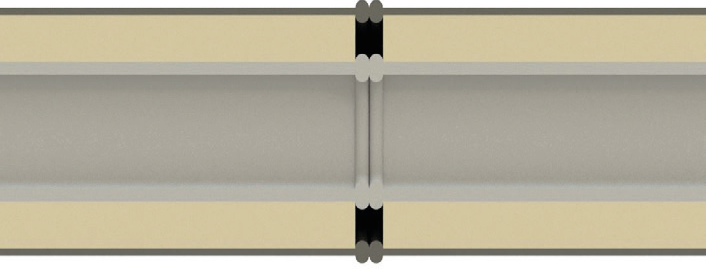

SIMULTANEOUS BUTT WELDING: BFx2 simultaneous butt welding involves joining two specially prepared pipes so that the primary PP-RCT pipe does not extend beyond the secondary HDPE coating, thus ending on the same joining level. The primary and secondary pipes are heated and welded simultaneously, creating the perfect seal junction. In addition, the insulation of the joining areas is completed at the same time as the welding, without having to restore the same later. This allows for extremely fast joining, excluding the burden of purchasing fittings and sealing kits, with a saving in installation time of more than 80% if compared to traditional installation systems. The external coating is perfectly sealed, without any possibility of water infiltration.

SIMULTANEOUS BUTT WELDING: BFx2 simultaneous butt welding involves joining two specially prepared pipes so that the primary PP-RCT pipe does not extend beyond the secondary HDPE coating, thus ending on the same joining level. The primary and secondary pipes are heated and welded simultaneously, creating the perfect seal junction. In addition, the insulation of the joining areas is completed at the same time as the welding, without having to restore the same later. This allows for extremely fast joining, excluding the burden of purchasing fittings and sealing kits, with a saving in installation time of more than 80% if compared to traditional installation systems. The external coating is perfectly sealed, without any possibility of water infiltration.

This method produces an integral system that guarantees high integrity of the components and high stability of the pipeline, thus allowing to easily carry out special underground installations such as those with controlled horizontal drilling (TOC or HDD, horizontal directional drilling).

WELDING OF PRE-INSULATED SPIGOT FITTINGS BFX2

To complete the line, pre-insulated PP-RCT ball valves, stub ends, flanges (free and removable) and transition fittings are available. They allow to start from the source and reach the user with a single valid system.

- Main Futures

- DATASHEET

- Documents

- CASE HISTORY

STRENGTHS

- Excellent insulation

- Low pressure drops

- Low specific weight

- Excellent weldability thanks to the joining systems of the NIRON range

- High corrosion resistance

- High chemical inertness and maximum resistance to chlorine-based disinfection systems

- High durability

- Joining reliability

- Excellent resistance to abrasion

- Maximum resistance to stray currents

- Quick installation, as joining is carried out with the classic joining systems (butt fusion welding, electrofusion welding) avoiding the use of accessories such as sealing kits (rigid foam half shells or pre-dosed kits in liquid polyurethane foam bottles), thus reducing installation times

- Safe installation, as we avoid contact of the insulation with the potentially dangerous two-component liquids (such as isocyanates) necessary to restore a standard system during the sealing phase

APPLICATIONS:

- transport of hot, cold, chilled, potable water, wastewater, and other aggressive liquids

- systems in residential, civil, industrial, and agricultural areas

- geothermal plants that exploit groundwater (e.g. plants fed with groundwater)

- POLYPROPYLENE SYSTEMS

- MULTILAYER SYSTEMS

- ENERGY SAVING SYSTEMS

- GAS & WATER DISTRIBUTION UNDER PRESSURE

- GAS & WATER DISTRIBUTION UNDER PRESSURE

- PLUMBING SYSTEMS

- WELDING UNITS

Niron Beta | β Grey PP-RCT Pipes and Fittings from DN20 mm to DN630 mm

Nero by Niron | PPR Pipes and Fittings with a duly UV stabilized POLYPROPYLENE outer layer

Polysystem | PP-R Pipes and Fittings for Plumbing and Heating Installations from DN16 mm to DN125 mm

Niron Preisolato | Innovative PRE-INSULATED Pipes and Fitting System suitable for applications where heat loss reduction is essential

Niron All Pro | Innovative PRE-INSULATED Pipes and Fitting System suitable for network for the distribution of hot fluids

Multinupi | Multilayer Pipes and Brass and PPSU Mechanical Pressure Fittings for the transport of Drinking Water

Multigeco | Multilayer Pipes and Total Flow Brass Fittings for the transport of Water & Gas

Nrgeo | Geothermal Exchangers for the exploitation of Subsoil Heat Energy

Polietilenetubi | Complete range of HDPE PE80 and PE100 Pipes from DN20 to DN1000 mm

Elopress | Complete range of Compression Fittings for the Distribution of Drinking Water and Fluids for Human Consumption

Elamid | PA12 Pipe and Fitting System for the transport of High Pressure Gas

Smartconduit | Non-hydroscopic composite Pipe and Fitting System designed to contain Electrical and Communication Cables in hazardous environments

Oiltech text= |

Smartlpg | Complete Pipe and Fitting System for the transport of LPG

Elosmart | Piping and Electrofusion Fitting System for Industrial Applications