Welding units

Nupi Industrie Italiane welding units are manufactured in compliance with Standard UNI 10566. They have been designed to weld all electrofusion fittings with 24-digit barcode system. Available on the market in conformity with Standard ISO 13950.

ELECTROFUSION WELDING UNITS

- AUTOMATIC WELDING UNIT SUPER LIGHT

- MANUAL WELDING UNIT FOR ELECTROFUSION FITTINGS

- MULTIFUNCTION AUTOMATIC WELDING UNIT

- MULTIFUNCTION AUTOMATIC WELDING UNIT INCORPORATED IN SUITCASE

- MULTIFUNCTION AUTOMATIC SMARTWELD WELDING UNIT INCORPORATED IN SUITCASE

AUTOMATIC WELDING UNIT WITH BARCODE SCANNER FOR ELECTROFUSION FITTINGS - SUPER LIGHT

Code: 00E9001SL

Conforms with CE requirements

Conforms with Standard UNI 10566 – MULTIFUNCTION type

Barcode reader conforming with Standard ISO 13950 and manual setting of time and voltage

Illuminated display with 4 lines, 20 characters each

Ambient temperature sensor

Connectors - 4 mm (art. 00S8305) with adaptors for 4,7mm (00S8203)

|

Technical characteristics: |

00E9001SL |

|---|---|

| Welding range | 20÷63 mm |

| Fitting working range | up to 20 Amp. maximum peak |

| Power supply | 230V E 50Hz/60Hz |

| Maximum power | 500 VA |

| Minimum power | 1,5Kw |

| Output voltage | da 5 a 42 volts |

| Power cable | L= 3 m |

| Welding cable | L=2 m |

| Dimensions | 210x115xH200 mm |

| Volume | 0,0048 mc |

| Weight | 6,5kg |

| Degree of protection | IP 54 |

| Working temperature | da-18° a + 55°C |

Basic equipment supplied with the welding unit: • User’s handbook on external support and quick guide on paper • Shipping box • Barcode scanner • Adapters with 4,7 mm pins

Additional equipment and spares: • 00BCSCAN: Barcode scanner

MANUAL WELDING UNIT FOR ELECTROFUSION FITTINGS

Code: 00E8500 / 00E8500L

Conforms with CE 89/392.

The welding unit was designed for the welding of all electrofusion fittings. The welding unit can be operated in seven different languages (Italian, English, French, Spanish, German, Dutch and Portuguese).

Welding data (time and voltage) are entered manually. During the welding cycle, the large backlit display shows the heating time, power consumption, voltage and energy used.

Illuminated display with 4 lines, 20 characters each

Ambient temperature sensor

Connectors - 4 mm (art. 00S8305) with adaptors for 4,7mm (00S8203)

|

Technical characteristics: |

00E9001 |

00E9001L |

|---|---|---|

| Welding range | 20÷630 mm | 20÷160 mm |

| Fitting working range | up to 80 Amp. maximum peak | up to 40 Amp. maximum peak |

| Power supply | 230V E 50Hz/60Hz | 230V E 50Hz/60Hz |

| Maximum power | 2.000 VA | 1.000 VA |

| Minimum power | 4 Kw | 3 Kw |

| Output voltage | from 5 to 42 V | from 5 to 42 V |

| Power cable | L= 4 m | L= 4 m |

| Welding cable | L= 4 m | L= 4 m |

| Dimensions | 340x500xH220 mm | 310x350xH160 mm |

| Volume | 0,0327 mc | 0,0104 mc |

| Weight | 20 kg | 15,6 kg |

| Degree of protection | IP 54 | IP 54 |

| Working temperature | From -18° to + 55°C | From -18° to + 55°C |

Basic equipment supplied with the welding unit: • User’s handbook • Shipping box • Adapters with 4,7 mm pins

Download

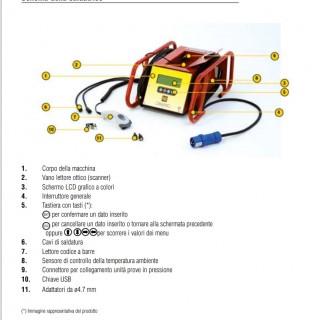

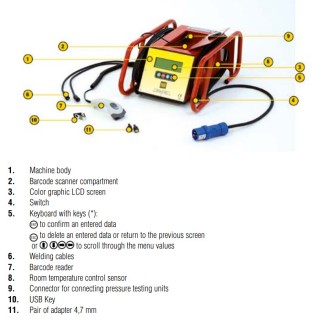

AUTOMATIC MULTIFUNCTION WELDING UNIT WITH BARCODE SCANNER FOR ELECTROFUSION FITTINGS

Code: 00E9001HW / 00E9001 / 19SSEL8404 / 00E9001L / 19SSEL8404L

Conforms with CE requirements

Conforms with Standard UNI 10566 – MULTIFUNCTION type

Barcode reader conforming with Standard ISO 13950 and manual setting of time and voltage

Graphic display LCD 480X278 pix (95x53mm)

Ambient temperature sensor

Connectors - 4 mm (art. 00S8305) with adaptors for 4,7mm (00S8203)

|

Technical characteristics: |

00E9001HW |

00E9001 19SSEL8404 |

00E9001L 19SSEL8404L |

|---|---|---|---|

| Designation ISO 12176-2 | P2 4US1VAKDX | P2 4US1VAKDX | P2 2US1VAKDX |

| Welding range | 20÷1000 mm | 20÷630 mm | 20÷160 mm |

| Fitting working range | up to 100 Amp. maximum peak | up to 100 Amp. maximum peak | up to 100 Amp. maximum peak |

| Welding Memory | 10.000 weldings | 10.000 weldings | 10.000 weldings |

| Pressure tests memory | 8 Memories with 500 parameters each for pressure tests | 8 Memories with 500 parameters each for pressure tests | 8 Memories with 500 parameters each for pressure tests |

| Power supply | 230V E 50Hz/60Hz | 230V E 50Hz/60Hz | 230V E 50Hz/60Hz |

| Maximum power | 5.000 VA | 4.000 VA | 1.000 VA |

| Minimum power | 6 Kw | 5 Kw | 3 Kw |

| Duty Cycle 60% | 90 Amp | 73 Amp | 27 Amp |

| Output voltage | from 5 to 42 V | from 5 to 42 V | from 5 to 42 V |

| Power cable | L= 4 m | L= 4 m | L= 4 m |

| Welding cable | L= 4 m | L= 4 m | L= 4 m |

| Dimensions | 310 x 500 x h205mm | 310 x 500 x h205mm | 310 x 450 x h170 mm |

| Volume | 0,0575 mc | 0,0575 mc | 0,0104 mc |

| Weight | 26,5 kg | 25,2 kg | 13,0 kg |

| Degree of protection | IP 54 | IP 54 | IP 54 |

| Working temperature | da-18° a + 55°C | da-18° a + 55°C | da-18° a + 55°C |

Basic equipment supplied with the welding unit: • User’s handbook on external support and quick guide on paper • Software for data download • Shipping box • Barcode scanner • Adapters with 4,7 mm pins

Additional equipment and spares: 00USBKEY: External support for data download (welding report, traceability, GPS coordinates and pressure test) • 00GPS: Global Positioning System • 00SENS: Pressure test unit • 00BCSCAN: Barcode scanner

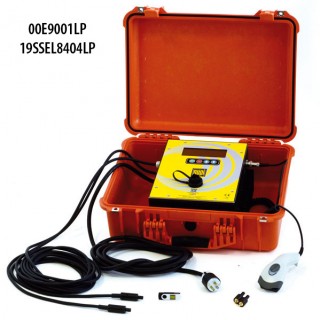

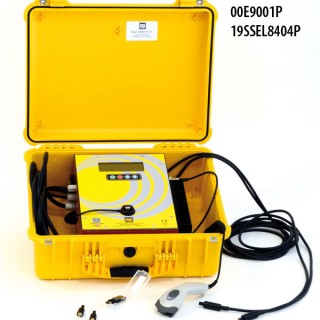

AUTOMATIC MULTIFUNCTION WELDING UNIT INCORPORATED IN SUITCASE

WITH BARCODE SCANNER FOR ELECTROFUSION FITTINGS

Code: 00E9001P / 19SSEL8404P / 00E9001LP / 19SSEL8404LP

Incorporated in the most innovative waterproof case. The case is watertight, waterproof, sand-proof, dust proof and able to withstand harsh environments and shocks. It is certified to withstand termperatures from -18 °C to 50 °C.

Conforms with CE requirements

Conforms with Standard UNI 10566 – MULTIFUNCTION type

Barcode reader conforming with Standard ISO 13950 and manual setting of time and voltage

Illuminated display with 4 lines, 20 characters each

Ambient temperature sensor

Connectors - 4 mm (art. 00S8305) with adaptors for 4,7mm (00S8203)

|

Technical characteristics: |

�??00E9001P |

00E9001LP |

|---|---|---|

| Welding range | 20÷400 mm | 20÷160 mm |

| Fitting working range | up to 80 Amp. maximum peak | up to 40 Amp. maximum peak |

| Welding Memory | 10.000 weldings | 10.000 weldings |

| Pressure tests memory | 8 Memories with 500 parameters each for pressure tests | 8 Memories with 500 parameters each for pressure tests |

| Power supply | 230V E 50Hz/60Hz | 230V E 50Hz/60Hz |

| Maximum power | 2.000 VA | 1.500 VA |

| Minimum power | 3 Kw | 3 Kw |

| Output voltage | from 5 to 42 V | from 5 to 42 V |

| Power cable | L= 4 m | L= 4 m |

| Welding cable | L= 4 m | L= 4 m |

| Dimensions | 510x436xH217 mm | 510x410xH200 mm |

| Volume | 0,0496 mc | 0,0418 mc |

| Weight | 24,0 kg | 16,0 kg |

| Degree of protection | IP 54 | IP 54 |

| Working temperature | da-18° a + 55°C | da-18° a + 55°C |

Basic equipment supplied with the welding unit: • User’s handbook on external support and quick guide on paper • Software for data download • Shipping box • Barcode scanner • Adapters with 4,7 mm pins Additional equipment and spares: 00USBKEY: External support for data download (welding report, traceability, GPS coordinates and pressure test) • 00GPS: Global Positioning System • 00SENS: Pressure test unit • 00BCSCAN: Barcode scanner

Download

AUTOMATIC MULTIFUNCTION SMARTWELD WELDING UNIT INCORPORATED IN SUITCASE

WITH BARCODE SCANNER FOR ELECTROFUSION FITTINGS

Code: 00SMARTWELD / 19SMARTWELD / 00SMARTWELDL / 19SMARTWELDLIGHT

The SMARTWELD welding machine associated to its NupiWeldingApp allows a total management of all information regarding construction site, welds, traceability of the products installed, installation mapping by GPS tracking and all subsequent testing activities.

Incorporated in the most innovative waterproof case. The case is watertight, waterproof, sand-proof, dust proof and able to withstand harsh environments and shocks. It is certified to withstand termperatures from -18 °C to 50 °C.

Conforms with CE requirements

Conforms with Standard UNI 10566 – MULTIFUNCTION type

Barcode reader conforming with Standard ISO 13950 and manual setting of time and voltage

Illuminated display with 4 lines, 20 characters each

Ambient temperature sensor

Connectors - 4 mm (art. 00S8305) with adaptors for 4,7mm (00S8203)

|

Technical characteristics: |

00SMARTWELD 19SMARTWELD |

00SMARTWELDL 19SMARTWELDLIGHT |

|---|---|---|

| Welding range | 20÷400 mm | 20÷160 mm |

| Fitting working range | up to 80 Amp. maximum peak | up to 40 Amp. maximum peak |

| Welding Memory | 10.000 weldings | 10.000 weldings |

| Pressure tests memory | 8 Memories with 500 parameters each for pressure tests | 8 Memories with 500 parameters each for pressure tests |

| Power supply | 230V E 50Hz/60Hz | 230V E 50Hz/60Hz |

| Maximum power | 2.000 VA | 1.500 VA |

| Minimum power | 3 Kw | 3 Kw |

| Output voltage | from 5 to 42 V | from 5 to 42 V |

| Power cable | L= 4 m | L= 4 m |

| Welding cable | L= 4 m | L= 4 m |

| Dimensions | 510x436xH217 mm | 510x410xH200 mm |

| Volume | 0,0496 mc | 0,0418 mc |

| Weight | 24,0 kg | 16,0 kg |

| Degree of protection | IP 54 | IP 54 |

| Working temperature | da-18° a + 55°C | da-18° a + 55°C |

Basic equipment supplied with the welding unit: • User’s handbook on external support and quick guide on paper • Software for data download • Shipping box • Barcode scanner • Adapters with 4,7 mm pins Additional equipment and spares: 00USBKEY: External support for data download (welding report, traceability, GPS coordinates and pressure test) • 00GPS: Global Positioning System • 00SENS: Pressure test unit • 00BCSCAN: Barcode scanner

SOCKET WELDER

- MANUAL SOCKET WELDER

- MANUAL WELDING MACHINE

Download

Code: 00NSBEP / 00NPCCE / 00NPCCE125

Manual socket welders for joining pipes and fittings, in compliance with the standards in force. They feature an aluminum heating plate and a practical, heat-insulated plastic handle.

They can weld HDPE, PP, PP-R, PVDF pipes and fittings, and they’re characterized by different shapes and working ranges, suitable for different applications.

|

Technical characteristics: |

00NSBEP |

00NPCCE |

00NPCCE125 |

|---|---|---|---|

| Welding range | 20÷32 mm | 16÷63 mm | 16÷125 mm |

| Power supply | 230V E 50Hz/60Hz | 230V E 50Hz/60Hz | 230V E 50Hz/60HzAs |

| Max absorbed power | 500 W | 800 W | 1400 W |

| Output voltage | from 5 to 42 volts | from 5 to 42 volts | from 5 to 42 volts |

| Dimensions | 115x50x320 mm | 175x50x360 mm | 175x50x360 mm |

| Volume | 0,0327 mc | 0,0104 mc | 175x50x395 mm |

| Weight (only wlder) | 1,44 kg | 1,82 kg | 3,16 kg |

| Supplied with die pair bushings | y | n | n |

| Shipping box | y | n | n |

| Working temperature | From -5° to + 40°C | From -5° to + 40°C | From -5° to + 40°C |

Basic equipment supplied with the socket welder: • User’s handbook • Shipping box (only for model 00NSBEP) • Fork support • Allen wrench • �??Pinn for socket and spigots

Additional equipment and spares: • Die pairs bushings included

Code: 00STL125

Workshop/construction site welding machine is suitable for the socket fusion of pipes and fittings up to an OD of 125 mm (¾” to 4”), in accordance with the standards in force. The machine is composed of a machine body featuring a selector for the welding depths of the different diameters, four self-centering steel clamps for locking pipes and fittings (different brands), a self-centring socket welder with electronic temperature control, a device for the maximum heating depth, a sliding trolley, a tripod to support the pipe, a set of sockets and spigots for socket fusion from Ø 25 to Ø 125 mm with steel case.

|

Technical characteristics: |

00STL125 |

|---|---|

| Welding range | 20÷125 mm |

| Power supply | 230V E 50Hz/60Hz |

| Max absorbed power | 1.400 W |

| Output voltage | from 5 to 42 volts |

| Dimensions | 1080 x 840 x 580 mm |

| Weight (only wlder) | 10 kg |

| Supplied with die pair bushings | y |

| Shipping box dimensions | 1500 x 800 x 1300 mm |

| Temperatura di lavoro | From -5° a + 40°C |

Basic equipment supplied with the socket welder: • Machine body complete with an electronic socket welder • Steel case complete with sockets and spigots from Ø 25 to Ø 125 mm and tool kit • Pipe support tripod • Sliding trolley

Basic equipment supplied with the socket welder: • Transport wooden case